حلول التغليف الكاملة JL3 تعزز ترقيات الأعمال

April 16, 2025

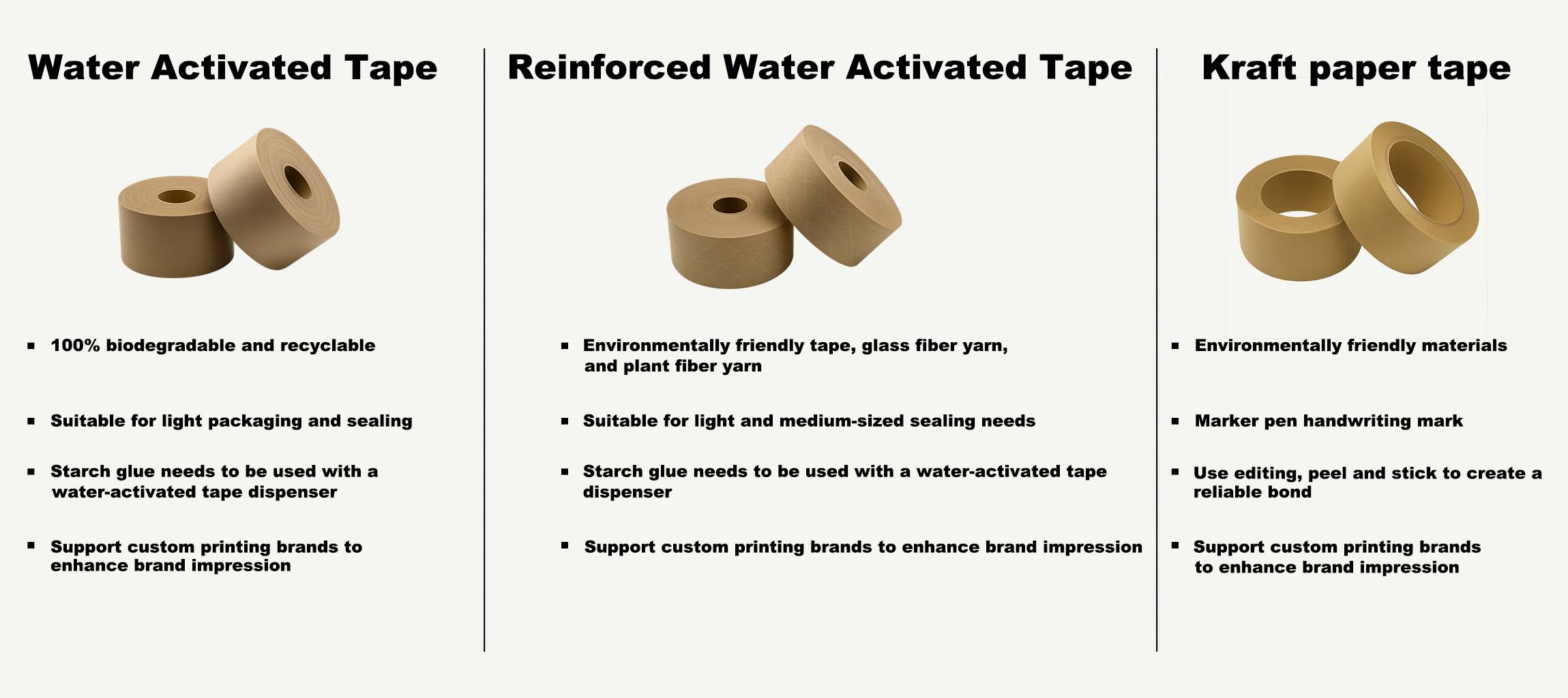

حلول التغليف الكاملة JL3 تعزز ترقيات الأعمال مع تحرك صناعة التعبئة والتغليف نحو الذكاء والتنمية المستدامة، توفر JL3، من خلال مجموعة منتجاتها المتنوعة وتكنولوجيتها المبتكرة، للمؤسسات العالمية حلاً كاملاً يتراوح من الأشرطة الصناعية المتخصصة إلى أشرطة ختم الكرتون الصديقة للبيئة وأنظمة التعبئة والتغليف الآلية بالكامل. ستمنحك هذه المقالة فهمًا عميقًا للمنتجات الأساسية لـ JL3 وأبرز ميزاتها التكنولوجية. المنتجات الأساسية: تغطية جميع احتياجات التعبئة والتغليف 1. الشريط المنشط بالماء (WAT): المزيج المثالي بين الحماية البيئية والقوة تستخدم سلسلة أشرطة JL3 المنشَّطة بالماء (WAT) ورق الكرافت كمادة أساسية، وصمغ النشا كمادة رابطة، وخيوط الألياف الزجاجية أو خيوط الألياف النباتية القابلة للتحلل كمواد تقوية، مما يُوازن بين الحفاظ على البيئة وقوة الشد. وهي مناسبة للصناعات عالية الطلب مثل التجارة الإلكترونية والأغذية والأدوية. خيوط الألياف النباتية: سلسلة JLN-39140: تستخدم ورق الكرافت كمادة أساسية، وصمغ النشا كمادة رابطة، وخيوط ألياف نباتية للتعزيز. وهي قابلة للتحلل الحيوي وإعادة التدوير بنسبة 100%، مما يجعلها مثالية لاحتياجات التغليف خفيفة الوزن. سلسلة JLN-39160: تستخدم ورق الكرافت كمادة أساسية، وصمغ النشا كمادة رابطة، وخيوط ألياف نباتية للتعزيز. وهي قابلة للتحلل الحيوي وإعادة التدوير بنسبة 100%، ومناسبة لاحتياجات التغليف متوسطة الوزن. خيوط الألياف الزجاجية: سلسلة JLN-8150: تستخدم ورق الكرافت كمادة أساسية، ولصق النشا كعامل ربط، وخيوط الألياف الزجاجية للتعزيز، وهي مصممة خصيصًا للخدمات اللوجستية خفيفة الوزن. سلسلة JLN-8160: تستخدم ورق الكرافت كمادة أساسية، ولصق النشا كعامل ربط، وخيوط الألياف الزجاجية للتعزيز، وهي مصممة للختم اللوجستي متوسط الوزن. شريط ورق كرافت غير مقوى: JLN-870: يستخدم ورق الكرافت كمادة أساسية ولصق النشا كعامل ربط، بدون تقوية الخيوط، مناسب لإغلاق الكرتون خفيف الوزن. JLN-8100: يستخدم ورق الكرافت كمادة أساسية ولصق النشا كعامل ربط، بدون تقوية الخيوط، مناسب لإغلاق الكرتون متوسط الوزن. أهم النقاط التكنولوجية: لاصق نشا ينشط عند ملامسته للماء، ويلتصق بإحكام بألياف الكرتون، مما يوفر مقاومة للرطوبة وقوة شد. بعد إغلاقه، لا يمكن العبث بالصندوق دون ترك أي أثر، مما يمنع السرقة بفعالية. يمكن لشريط واحد من الشريط إكمال عملية إغلاق الجزء العلوي، مما يقلل من هدر المواد ويوفر التكاليف للشركات. 2. شريط الألياف: ربط وتثبيت صناعي بالنسبة لاحتياجات الربط في الأنابيب الفولاذية ومواد البناء والأجهزة المنزلية والتعبئة والتغليف، توفر أشرطة الألياف أحادية الاتجاه وثنائية الاتجاه من JL3 أداءً ممتازًا: سلسلة JLT-602: مناسبة لاحتياجات التغليف الخفيف وختم الكرتون، مع الحفاظ على أداء الشد الجيد. سلسلة JLT-607A: تصميم قابل للإزالة بشكل نظيف، مناسب لحماية سطح الأثاث والأجهزة، ولا يترك أي مادة لاصقة متبقية. سلسلة JLW-323: تقوية الألياف ثنائية الجانب وثنائية الاتجاه، مناسبة للأرضيات الرياضية، وختم الأبواب والنوافذ، وتطبيقات السيارات. شريط السيناريو الخاص: سلسلة JLT-5160: مصنوعة من الألياف الكيميائية، ومناسبة لصناعات البناء والجسور، وتوفر قوة شد تبلغ 1800 نيوتن/40 مم. سلسلة JLW-695: مقاومة للزيت ومقاومة لدرجات الحرارة العالية، ومناسبة للمحولات، وتوفر وظائف الحماية والصيانة والعزل. 3. سلسلة موزعات الشريط اللاصق المنشَّط بالماء: خيارات من اليدوي إلى الأوتوماتيكي بالكامل تتميز موزعات الش...

English

English Deutsch

Deutsch español

español العربية

العربية 中文

中文

شبكة IPv6 مدعومة

شبكة IPv6 مدعومة